“It is hard to believe that NASA Mars rover Curiosity celebrated its eighth year of operation on the Red planet. To have our Washington State manufactured products on Mars is a matter of great gratification for us.”

– Jim Wright owner and founder of JET CITY LASER in Auburn, WA

Jim Wright

Laser Engraved NASA Mars Rover Sundial. Photo credit NASA

In mid-2000, the University of Washington first selected and NASA approved Jet City Laser to laser engrave informational and product identification on NASA Mars rover sundial items.

Jim Wright, the founder of Jet City Laser, personally engraved the face and sides of the Martian sundials launched on board the Mars rovers Spirit and Opportunity.

“I wanted everything to be perfect… a work of art.” Says Mr. Wright.

NASA has manufactured five robotic rovers for the Mars exploration effort. They are:

- Sojourner (1996)

- Spirit (2003)

- Opportunity (2003)

- Curiosity (2011)

- Perseverance (launched 7/2020; landed 2/2021)

Jim Wright explains:

“We approach the opportunity to be a small part of America’s space program with a lot of pride.”

“We did product identification work on the sundial on the Spirit and Opportunity Rovers. We did the sundial and the sabot part of the parachute deployment system for Curiosity and we did some load dispersion pads for Perseverance”.

The Science and Art Behind Jet City Laser

Jet City Laser dba UID2go uses a variety of technologies for part identification and traceability which include:

- Laser engraving

- Chemical etching

- Photographic imaging

- RFID

In the Mars rover projects, the NASA selected subcontractor specified the process to use, the subcontractor defined the base material to engrave and provided detailed engineering drawings and instructions.

The specification for these projects required the use of laser engraving.

Shop technician pre-checks laser engraver setup.

Based on years of experience in material processing using lasers, Jet City Laser engineers selected one of the three laser wavelengths available to them, then further narrowed the process to be selected from one of two beam delivery technologies available. The goal was to provide a high resolution, high contrast, high precision, permanent mark on the customer specified base material.

Laser etched black anodized aluminum exhibits bright white characters

The Art of Laser Engraving

The art of engraving is in understanding the possible end results of choosing different image patterns that can be engraved by programming the laser beam to travel across a particular path. The laser beam’s engraving path and the focal plane are carefully chosen to achieve a consistent removal depth of material. For example, sometimes, non-crossover beam paths are desirable to ensure that each etched surface is exposed to the heat of the laser beam only once. This technique minimizes micro-fracturing of the base material and assures removal of the same amount of material throughout the final image.

On some base materials where micro-fracturing may not be of concern, a 90-degree crosshatch is desirable for controlling the final image’s reflected light. The crosshatch pattern obtains the best contrast when viewing under natural light.

Where are the NASA Mars Rover Parts Engraved by Jet City Laser Now?

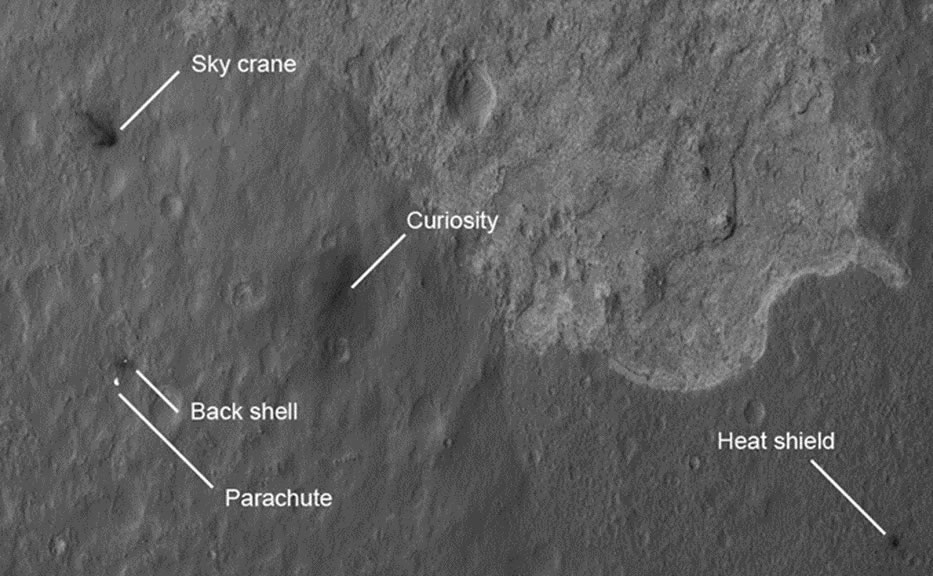

NASA Mars rover Curiosity landed on Mars in 2012. The August 07, 2012 image below is a photo of the Mars Curiosity landing site, taken by an orbiting satellite.

Jet City Laser’s products are on the parachute back shell and on the Curiosity itself.

“Scene of a Curiosity Rover Martian Landing” image credit NASA/JPL-Caltech/Univ. of Arizona

Perseverance rover wheels folded ready for final assembly. Photo credit NASA/JPL-Caltech/KSC

Jet City Laser’s products are on the parachute back shell and the Perseverance.

NASA stock photo of the Perseverance rover, with its six wheels folded up as it is being packed into its back shell and parachute assembly (center) before attachment of the spacecraft’s heat shield (bottom). A planetary cruise stage (top) will provide power and communications during the rover’s voyage to Mars.

NASA Mars Rover Mission Updates

SOJOURNER ROVER MISSION UPDATE – 1996 through 1997

Sojourner spent 83 days of a planned seven-day mission exploring the Martian terrain, snapping photographs, and taking chemical, atmospheric and other measurements. The rover had its last communication session with Earth at 3:23 AM PDT on September 27, 1997.

SPIRIT ROVER MISSION UPDATE – 2003 through 2011

The Spirit rover stopped communicating on March 22, 2010. After attempting more than 1,300 upload commands to the Spirit as part of a recovery effort, NASA concluded its recovery efforts on May 25, 2011. During its operational life on the Red planet, the Spirit rover traveled 4.80 miles.

OPPORTUNITY ROVER MISSION UPDATE – 2003 through 2019

On June 10, 2018, a planet-wide dust storm effectively coated the solar battery recharging system. The last uplink to the rover Opportunity was attempted on February 12, 2019. With no response, the rover recovery efforts were concluded, and the Opportunity mission was officially considered complete. During its operational life on the Red planet, the Opportunity rover traveled 28.06 miles.

CURIOSITY ROVER MISSION UPDATE -2011 and Ongoing

Launched: November 26, 2011; Landed on Mars: August 6, 2012

PERSEVERANCE ROVER MISSION – 2020 and Ongoing

- Launched: July 30, 2020, at 4:50 AM PDT

- Landed: February 18, 2021

- First flight of interplanetary helicopter Ingenuity: April 19, 2021; Ingenuity climbed 10 ft. / 3 m in the air

- Ingenuity completed six planned flights as of May 24, 2021

- As of June 1, 2021, Perseverance collected numerous soil samples and took more than 77,000 images; view images

- Mission Duration: at least one Mars year (about 687 Earth Days)

- Get the latest updates on the Mars rover Perseverance and the Mars helicopter Ingenuity

Call Jet City Laser today at 206-623-4949 or contact us online for more information about laser engraving for your project.

Credits and Citations

- Mars Rover Sundial. Photo credit NASA

- Where are the Jet City Laser engraved rover parts now? Information excerpts https://mars.nasa.gov/resources/4299/scene-of-a-martian-landing/

- “Scene of a Martian Landing” image credit NASA/JPL-Caltech/Univ. of Arizona https://www.nasa.gov/mission_pages/msl/multimedia/PIA16001.html

- Perseverance rover wheels folded ready for final assembly. Photo credit NASA/JPL-Caltech/KSC https://mars.nasa.gov/resources/25060/one-last-earthly-look/

- Mars Rover Mission Updates https://mars.nasa.gov/

- Jet City Laser – Laser Engraved Nameplates

- Jet City Laser – NASA Two Worlds, One Sun: Missions Complete.